Beyond generic solutions, in today's ceramics industry, competitiveness is defined by the ability to accurately manage complex and variable processes. Growing regulatory demands, increasingly stringent quality standards and the need to optimize resources have made...

Differential Pressures in the Glaze Plant

The need to digitalize the differential pressure control of their plant filters was identified to improve data traceability and centralize information in a single monitoring system. Until then, monitoring required local manual readings, with no historical record or...

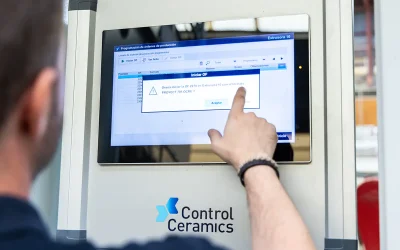

We turn your ceramic factory into a smart machine

The operator as the key to success At Ingesom we understand that the real engine of any factory is not only the machines, but the people who operate them every day. We turn your ceramic factory into an intelligent machine, which is why our main strength is based on...

Goodbye to overstock! Control Ceramics revolutionizes ceramic production: only manufacture what you sell

Control Ceramics revolutionizes ceramic production Have you ever imagined a ceramic factory that produces what it sells, without accumulated inventory or overstock costs? Sure you do. With Control Ceramics, the MES system specifically for the ceramic industry, you...

Control Ceramics CMMS, industrial maintenance in the ceramics industry

Control Ceramics CMMS In demanding industrial environments, having a digitized maintenance system has become a critical option. Therefore, the development of Control Ceramics CMMS as a module of Control Ceramics was a must. Why digitize maintenance? Industrial...

Industrial data acquisition for the ceramics sector

Industrial data acquisition for the ceramics industry Digital transformation in the ceramics industry starts with capturing data from the production process in real time. The need has become immediate and critical for any plant that aspires to improve efficiency,...

Turn data into decisions: how an MES system boosts your KPIs and maximizes profitability

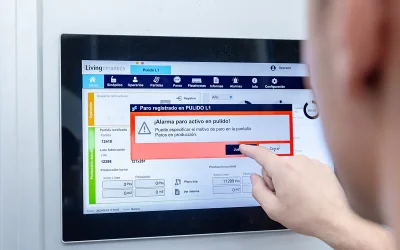

In today's competitive industrial sector, the ability to transform data into effective decisions is essential to achieve operational excellence and maximize profitability. MES systems have established themselves as fundamental tools to achieve this goal, providing...

The difference between having or not having a MES System in your ceramic factory

Implementing an MES (Manufacturing Execution System) in a ceramics factory can transform workflow and efficiency compared to not having one. Here's the difference in some key aspects: 1. Production control and visibilityWithMES: provides a real-time view of the entire...

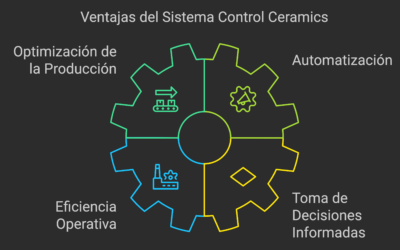

Advantages of the MES Control Ceramics system

The MES Control Ceramics system is specifically designed to optimize production in the ceramics industry. Thanks to its advanced technology and focus on automation, it not only improves operational efficiency, but also provides valuable tools for informed decision...

100% paperless: driving efficiency in the ceramics industry

Digitization is a key driver of efficiency and competitiveness in the ceramics industry. Adopting 100% paperless factory management not only optimizes processes, but also contributes to sustainability and reduced operating costs. 100% paperless keys Improved...

Control Ceramics, much more than a MES System

The first half of 2024 has been a success thanks to you. The launches of Ceramics Energy Control y Control Ceramics CMMS have been decisive to continue advancing in the offer of digitalization systems that cover all the needs of the ceramic industry, as well as those...

Monitor the energy consumption of your ceramic factory

Still not monitoring the energy consumption of your ceramic factory? Direct influence on production Efficiency in ceramics production is closely linked to energy consumption. A monitoring system allows immediate detection and troubleshooting, reducing downtime and...